Simply. Eco-friendly. Cheap

We create new printable technologies for solar cell creation

Unique technologies

for CIGS solar cells

NanoInk Technologies

Our product is nanocomposite ink for creating CIGS solar cells by printing methods. This avoids the use of expensive equipment for the production of CIGS solar cells.

It is enough to use a printer to print a photoactive layer, the remaining stages of production remain the same as in the classical production of CIGS solar cells.

It is enough to use a printer to print a photoactive layer, the remaining stages of production remain the same as in the classical production of CIGS solar cells.

Our developed ink is a nanocomposite powder dispersed in various solvents with additives. The unique recipe of preparation and developed application techniques allow you to apply ink to almost any surface. Both printing technologies (such as dr Blade) and spraying technologies (spay coating) can be used as application techniques.

Apply our technologies to reduce the cost of producing solar cells and simplify the manufacturing process.

the cost of electricity from PV in w/$

Our technologies allow:

easily scale production volumes

consume 4 time less raw materials than CIGS by sputtering

easy start of new product lines due to cheap equipment

reduce energy consumption during production

CIGS advantages

CIGS technology is a thin–film technology for creating solar cells. The thickness of the entire solar battery is 5 microns, which is 20 times less than the thickness of a human hair.

The energy conversion efficiency reaches 23%. The technology makes solar panels flexible and lightweight, which facilitates their use and opens up new opportunities for integrating solar cells into buildings (BIPV) and products (VIPV).

The technology already occupies 12% of the global photovoltaics market and has proven itself in real conditions.

The energy conversion efficiency reaches 23%. The technology makes solar panels flexible and lightweight, which facilitates their use and opens up new opportunities for integrating solar cells into buildings (BIPV) and products (VIPV).

The technology already occupies 12% of the global photovoltaics market and has proven itself in real conditions.

BIPV

Low-power IoT electronic

Rooftop

Cars

CIGS applications

How do we synthesize ink?

We synthesize nanocrystals

We use the hot injection method for the synthesis of nanocrystals.

We synthesize nanocrystals

We use the hot injection method for the synthesis of nanocrystals.

Create powder from nanocrystals

Vacuum drying is used.

Create ink

We use thinners and additives for high viscosity inks.

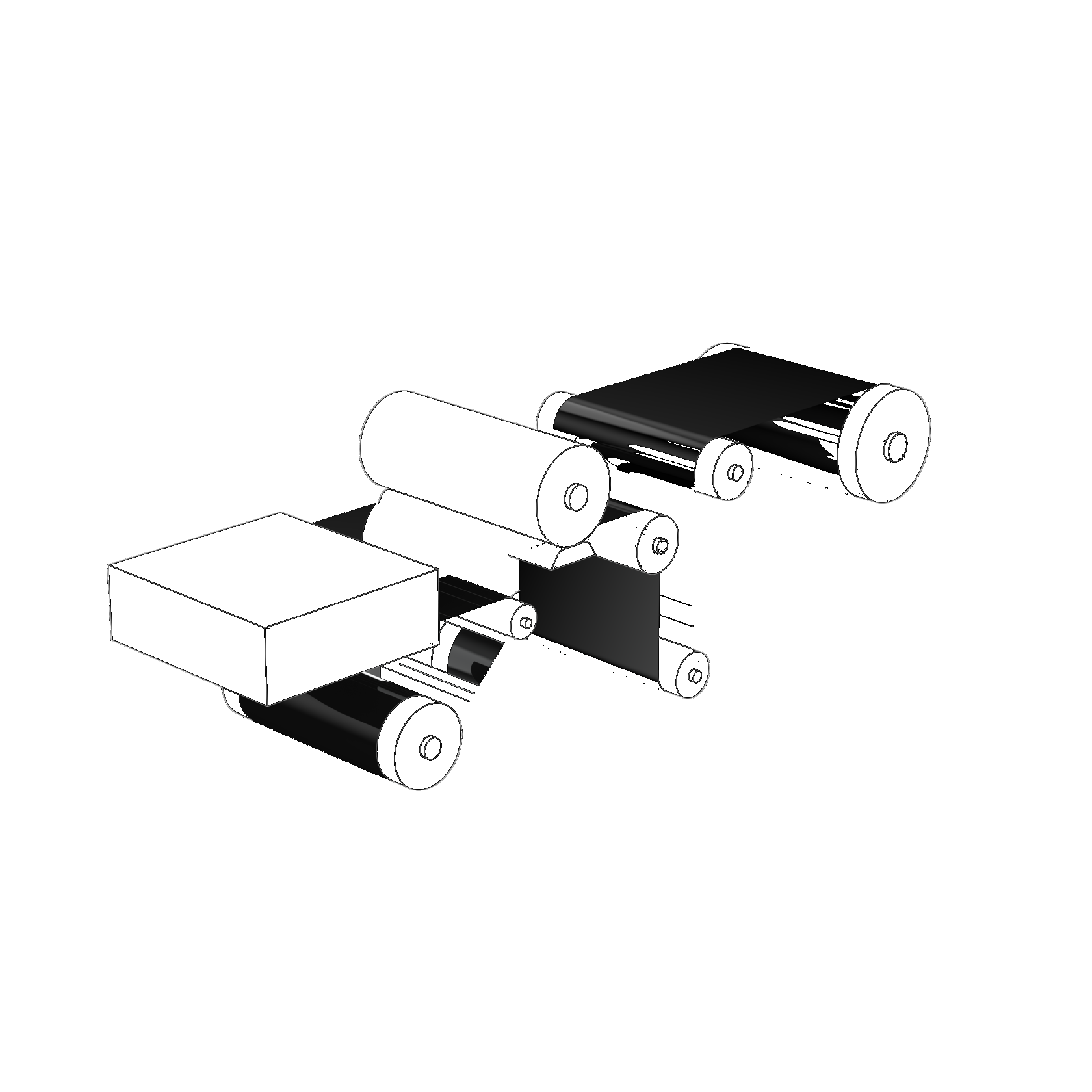

Applying ink

We use several application methods to create CIGS.

Applying ink

We use several application methods to create CIGS.

Welcome to the NanoInk laboratory

NanoInk is an innovative company for the development of new photovoltaics technologies. We are a team of strong specialists in the field of chemical synthesis and solar energy technologies. We have our own equipment for the synthesis and production of CIGS solar cells for the production of test solar cells. Some of our equipment is our intellectual property and has patent protection.

We produce ink for photovoltaics using CIGS-printing methods and develop our own ink application methods, which allows us to reduce the number of technological processes and reduce the cost of producing solar cells.

We produce ink for photovoltaics using CIGS-printing methods and develop our own ink application methods, which allows us to reduce the number of technological processes and reduce the cost of producing solar cells.

NanoInk team

The Nanoink team is a pool of specialists who have accumulated a wealth of experience and gained huge competencies in the photovoltaics sector.

- Lev LogunovСЕОAuthor of 19 articles in high-ranking journals and 4 patents. Head of three research grants.

- Nadezhda YakubovskayaProject ManagerITMO Innovative Entrepreneurship. Administrator of the NWCCTT startup group, ITMO Engineering Center.

- Maxim MiropoltsevEngineerMaster's Degree in Photonics and Optoinformatics. Postgraduate student of the Faculty of Photonics ITMO.

- Anton TkachEngineerMaster's Degree in Photonics and Optoinformatics.

- Sergey MakarovScientific consultantAuthor of more than 200 scientific articles in publications indexed by the Web of Science and Scopus databases.

- Victoria ZheltovaBusiness consultantHead of the Engineering Center at ITMO University. Head of startups created on the basis of the North-West Center for Technology Transfer.

Send us a message

We'll get back to you ASAP